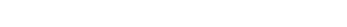

3M’s TRIZACT™ Diamond Tile (TDT) is another powerful tool in UPI’s arsenal of stock removal options. It not only removes material faster than coarse slurries or fixed pellets with less subsurface damage, but does so without the messy residue of slurry lapping. Used commercially to lap a wide variety of hard ceramics and brittle substrates like fused quartz/silica, borosilicate optical glass, sapphire, and glass ceramics such as Zerodur™, TRIZACT™ Diamond Tile is an ideal solution for lapping a multitude of substrates on conventional single or double-sided lapping machines using water-based grinding coolants.

TRIZACT™ Diamond Tile grew out of the search for bonded fixed abrasives with longer life of finer grade products. Unlike conventional abrasives, superabrasives require a bond structure that is simultaneously rigid and flexible. TDT’s fixed abrasive technology combines an organic polymeric binder with an inorganic abrasive (diamond) composite multi-replicated continuously to expose the lower lying abrasive.

Fundamental to TRIZACT’s™ fixed abrasive technology is abrasive conditioning with two separate and distinct operations. Initial conditioning, a.k.a. pad break-in, removes a thin layer from the surface exposing the fixed abrasives used for cutting. Pad break-in improves surface flatness and yields a stable substrate removal rate. For TDT, break-in wear is recommended between 40-75 microns. Pad dressing or pad conditioning happens throughout the life of the pad and is operation dependent. Ongoing conditioning determines pad wear amounts, which improve flatness and keep removal rates to appropriate levels. Factors affecting pad wear are diamond size, lapping machinery and conditions, substrate material, and total substrate removal.

A key advantage of TRIZACT™ is that low pressures can be used optimizing benefits. Lower pressures result in lower subsurface damage, while TDT’s diamond abrasive still maintains higher removal rates. Lower pressures can also provide improved bow and warp on parts being processed, as well as improve overall flatness.

Conventional abrasives are hard-pressed to compete with diamond. Usually, higher cost is what prevents diamond use, but TRIZACT’s™ fast, consistent cut rates, finer finishes, and reduced process time increase productivity and reduce cost.

Universal Photonics is the sole North American distributor for 3M’s TRIZACT™ Diamond Tile. It is available in a variety of micron sizes, along with the silicon carbide pucks used for conditioning and UPI’s depth gauge to measure amount of available throughout the lapping process also has a selection of water-based coolants to meet specific application needs.